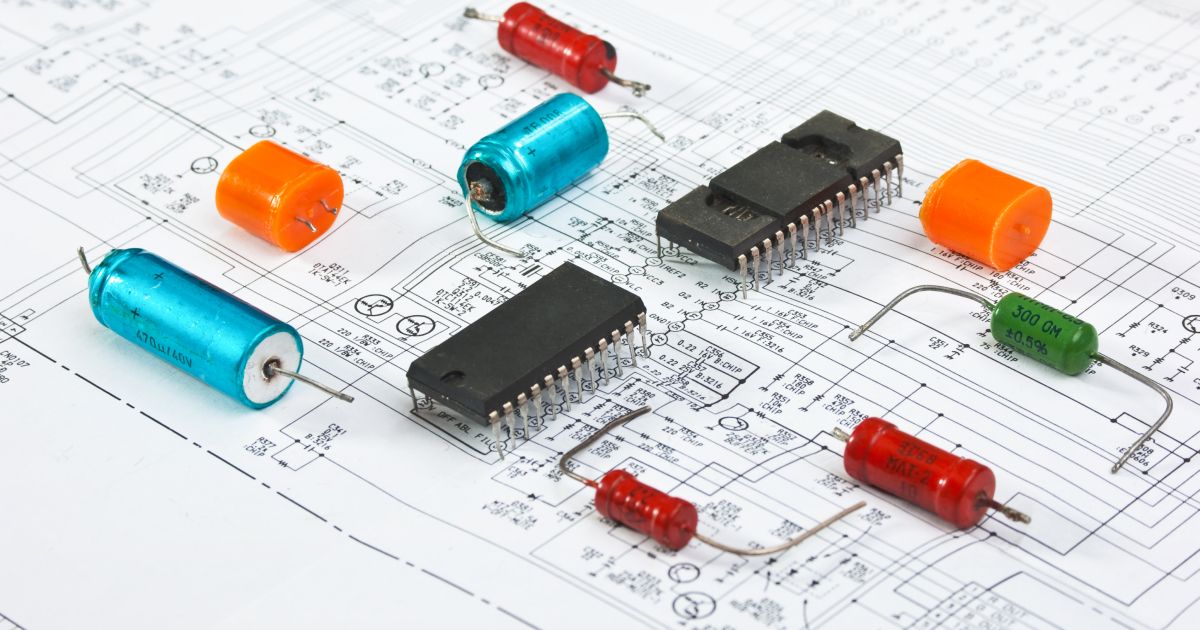

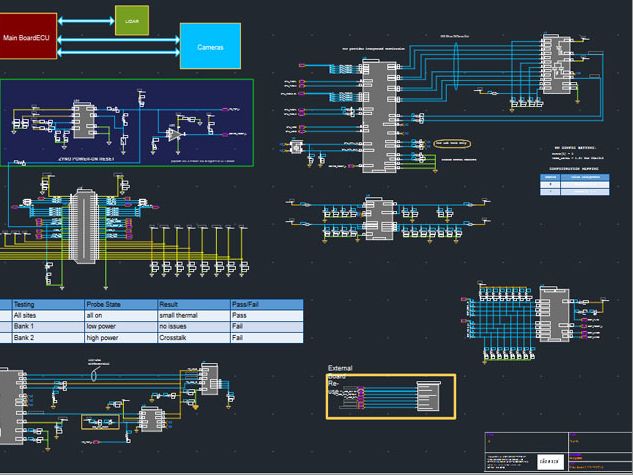

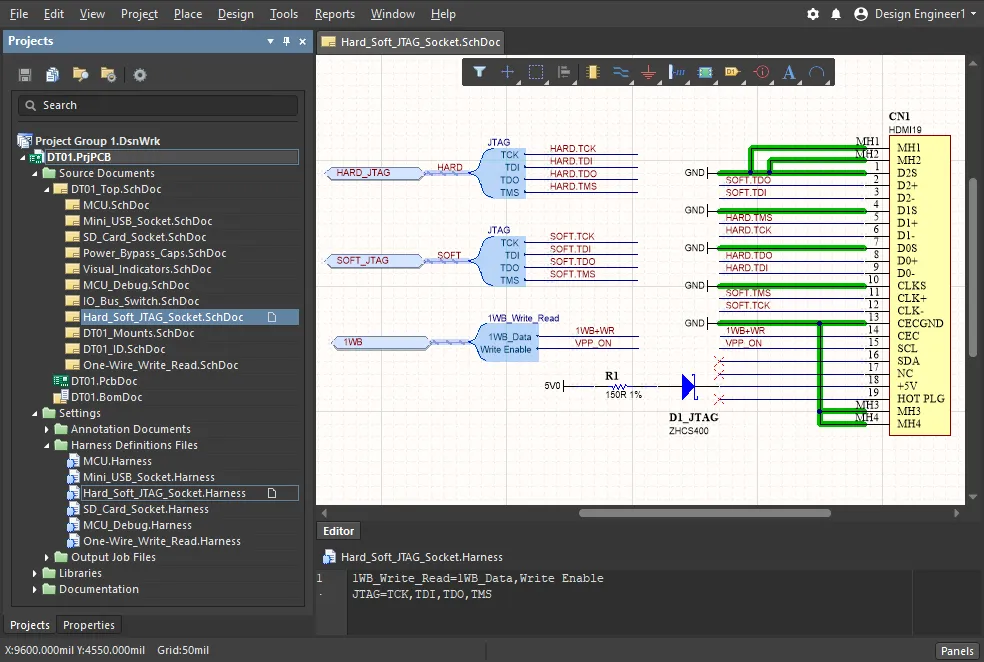

Comprehensive Schematic Design Services

We specialize in delivering comprehensive schematic design services for next-generation automotive electronic systems. Our engineering capabilities span the full spectrum of on-board electronics, enabling us to support customers from early concept development to production-ready designs.

Our expertise includes complex power architectures (DC/DC converters, high-voltage/low-voltage domains, protection and supervision circuits), automotive Ethernet and high-speed communication interfaces, memory subsystems (DDR, LPDDR, eMMC, NOR/NAND Flash), as well as MCU- and SoC-based processing platforms. We design with strict adherence to automotive standards such as AEC-Q100, ISO 11452, CISPR 25, and functional safety requirements up to ASIL-D.

Beyond schematic design, we incorporate signal-integrity and power-integrity considerations, EMI/EMC-optimized circuitry, redundancy concepts, diagnostics, and safe-state behavior. Our team has extensive experience working with OEM and Tier-1 engineering processes, ensuring that all designs meet stringent reliability, manufacturability, and qualification expectations.

By combining deep technical expertise with strong domain knowledge, we provide high-quality, scalable, and future-proof electronic designs that accelerate our customers’ development cycles and reduce program risk.

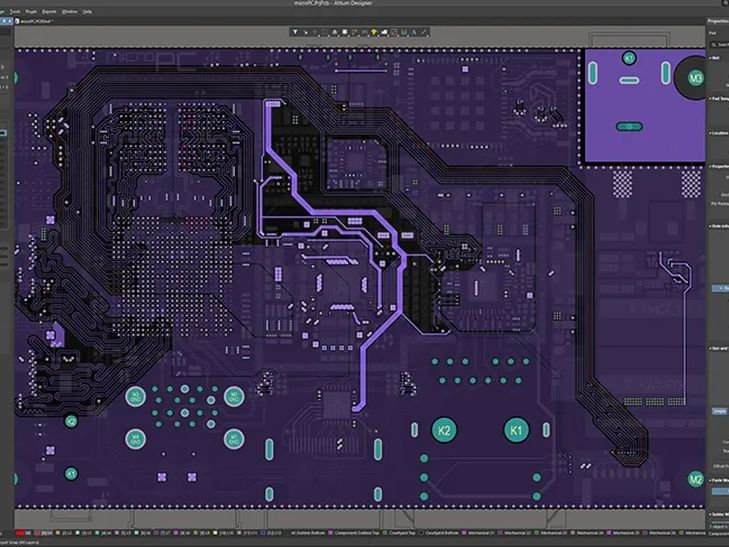

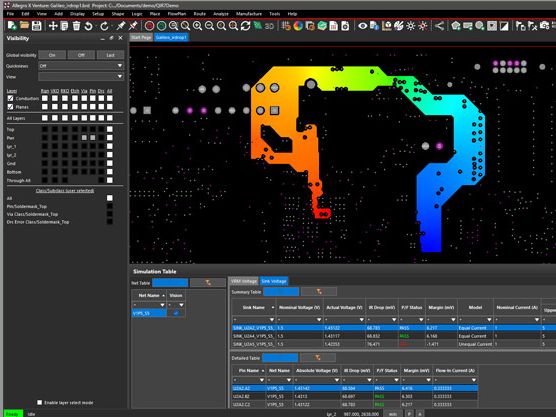

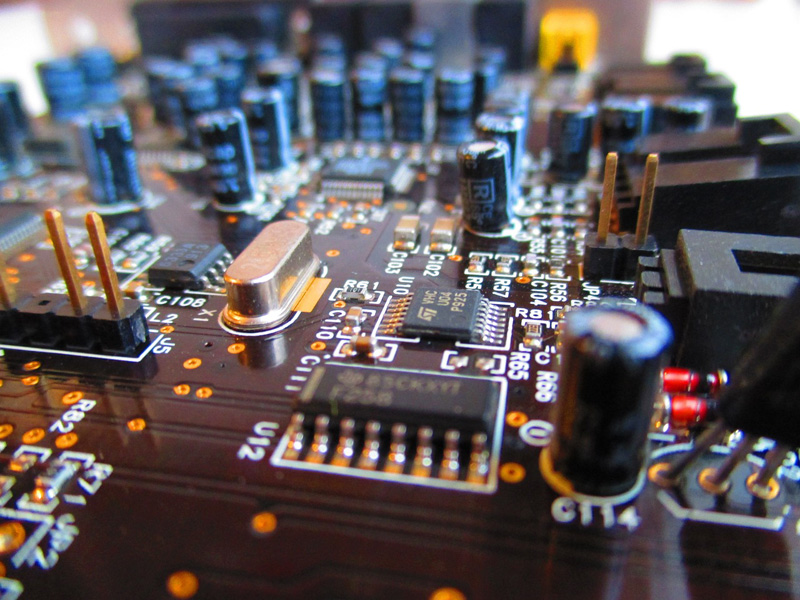

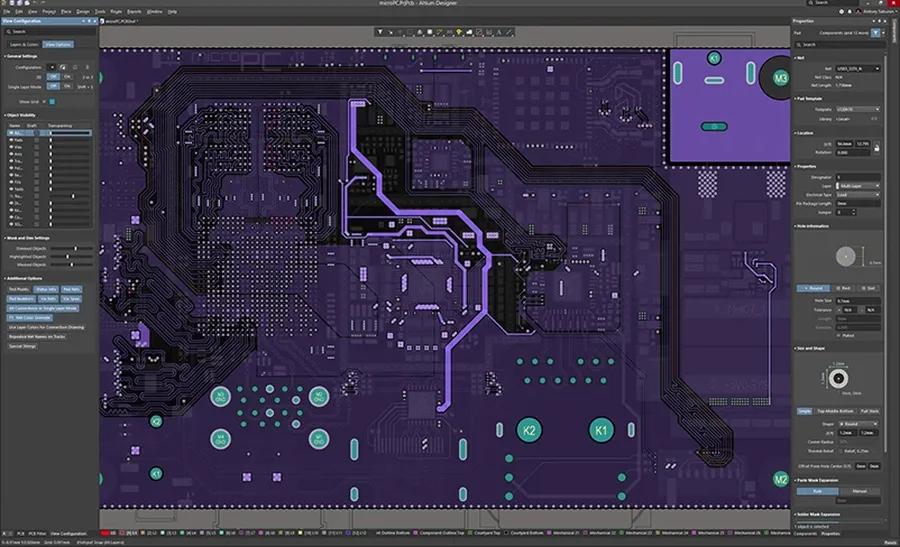

Professional PCB Layout Design Services

We provide high-quality PCB layout design services tailored for automotive electronic systems. Our work integrates high-speed design techniques, EMC compliance strategies, manufacturability considerations, and cost-optimized implementation to deliver reliable, production-ready PCBs.

We support complex designs involving MCU/SoC platforms, DDR/LPDDR memory interfaces, automotive Ethernet (100BASE-T1 / 1000BASE-T1), CAN/CAN-FD, mixed-signal circuits, and power electronics. Our layout approach includes controlled-impedance routing, length matching, differential pair optimization, clean return-path design, and topology-based high-speed strategies to ensure strong signal integrity.

For EMC performance, we apply structured layer stack-ups, noise zone isolation, stitching via patterns, optimized grounding, and proper placement of filters and protection devices—meeting CISPR 25, ISO 11452, and OEM requirements.

We design with DFM/DFA principles in mind, ensuring efficient component placement, manufacturable routing, assembly-friendly footprints, and fabrication-tolerant via structures. Cost is optimized through material selection, stack-up efficiency, layer-count balancing, and via-technology choices.

By combining technical expertise with strong automotive experience, we deliver robust and efficient layouts that meet performance, EMC, and manufacturing standards while reducing project risk and time-to-market.

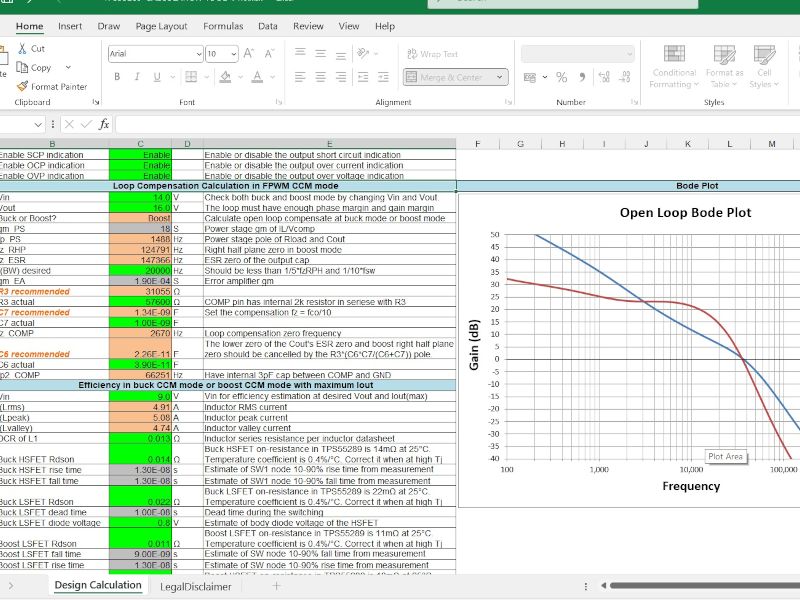

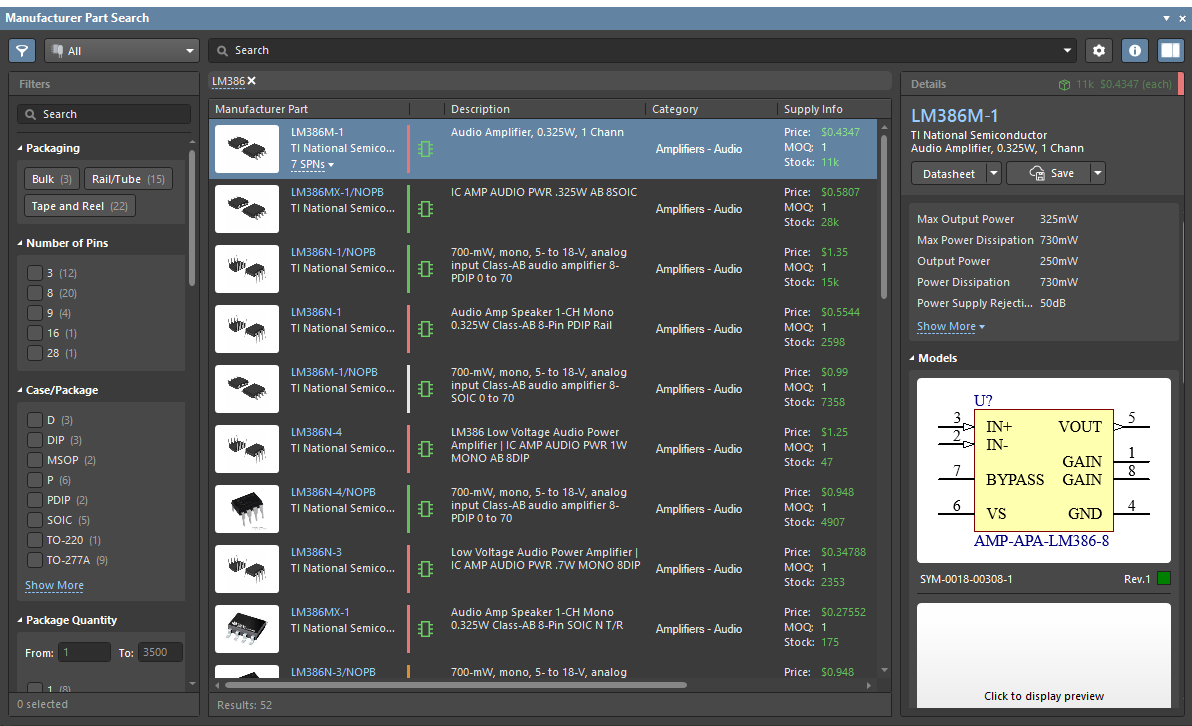

Component Shortage Mitigation Support

We provide comprehensive support to help customers navigate global component shortages and supply-chain disruptions. Our engineering team proactively identifies at-risk components, evaluates second-source and pin-compatible alternatives, and performs rapid design reviews to validate electrical, thermal, and functional compatibility.

When drop-in replacements are unavailable, we offer fast redesign services—adjusting schematics, updating PCB footprints, and validating system behavior to ensure performance and reliability are maintained. Our supply experts also work closely with distributors and manufacturers to secure feasible sourcing paths and long-term continuity plans.

By combining technical expertise with supply-chain awareness, we help customers reduce production delays, minimize redesign risks, and maintain stable product delivery even under severe component scarcity.

Localized IC Design Support

We provide localized IC design support to help customers overcome part shortages, regional supply constraints, and long lead-time challenges. Our team works closely with semiconductor partners and design houses to identify pin-to-pin compatible replacements, evaluate functional and electrical equivalence, and redesign peripheral circuits when needed.

Beyond simple component substitution, we support localized IC redesign and customization—adapting existing architectures to meet local manufacturing capabilities, regulatory requirements, and cost targets. This includes datasheet reverse-mapping, footprint and PCB migration, signal-integrity validation, power domain review, and production readiness assessment.

Our localized IC services enable customers to secure long-term supply continuity, reduce dependency on constrained global components, and accelerate product delivery without compromising performance, safety, or reliability.