MobileScope Description

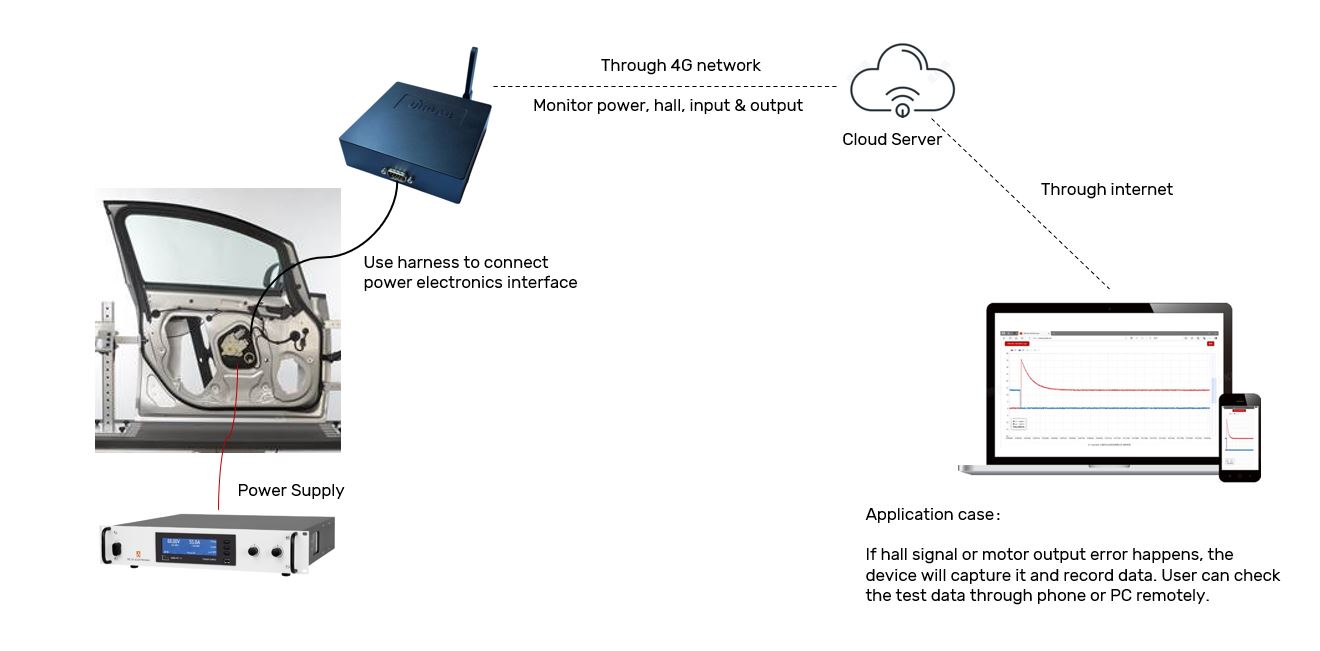

Meet a new generation of portable data acquisition—compact, powerful, and built for real-world testing. Similar in size to a handheld camera, this device delivers professional-grade measurement capabilities anywhere you go. With up to 8 hours of battery-powered operation, it keeps working long after traditional instruments need to shut down.

Whether you're validating vehicle systems or troubleshooting issues in the field, the device gives you full control from your phone or computer through seamless cloud connectivity. Its multi-channel capture, intelligent trigger functions, and onboard data search make it easy to pinpoint the information you need—quickly and accurately.

Lightweight, durable, and ready for any environment, it’s the ideal solution for engineers who need reliable data anytime, anywhere.

Technical Parameters

| Parameter | Conditions | Min | Typ | Max | Unit |

|---|---|---|---|---|---|

| Voltage Channel | Input impedance 1MΩ | 4 | Ch | ||

| Voltage Accuracy | When input voltage amplitude >= 2V | -1 | +1 | % | |

| Voltage Accuracy | When input voltage amplitude < 2V | -0.1 | +0.1 | V | |

| Voltage Range | -100 | 100 | V | ||

| Voltage Sample Rate | 1K | 1M | S/s | ||

| Data Record Length | When sample rate is 1MS/s | 33 | sec | ||

| Data Record Length | When sample rate is 1K/s | 9 | hour | ||

| Data Record Section | 32 | ||||

| Battery Support Time | 8 | hour | |||

| Ambient Temperature | -20 | 25 | 55 | °C |

Application Scenario

MobileScope is a versatile measurement and diagnostic platform designed for comprehensive vehicle testing and development. It enables engineers to capture and analyze real-time vehicle data across multiple domains, supporting activities such as:

Vehicle Data Measurement: Acquire high-resolution signals from sensors, ECUs, and in-vehicle networks for accurate system monitoring

Validation DV/PV Test: Conduct Development Validation (DV) and Production Validation (PV) testing, to debug any issue in DV/PV

Technical Issue Debug: Quickly identify and troubleshoot complex hardware and software issues in embedded automotive systems.

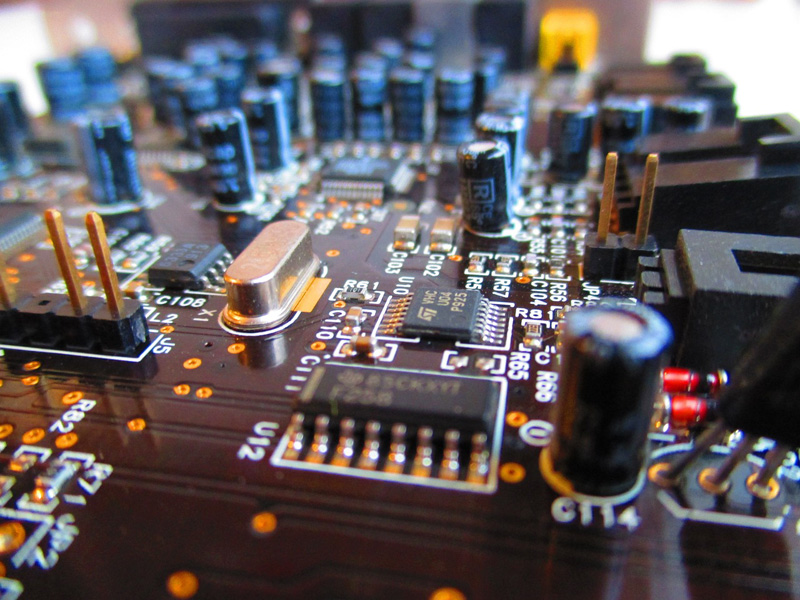

Hardware and Software Development: Support iterative development of ECUs, sensor modules, and integrated automotive platforms, accelerating prototyping and verification cycles.

By combining flexible data acquisition, high-precision analysis, and real-time monitoring, MobileScope streamlines vehicle testing workflows and enhances the reliability, performance, and safety of automotive electronic systems.

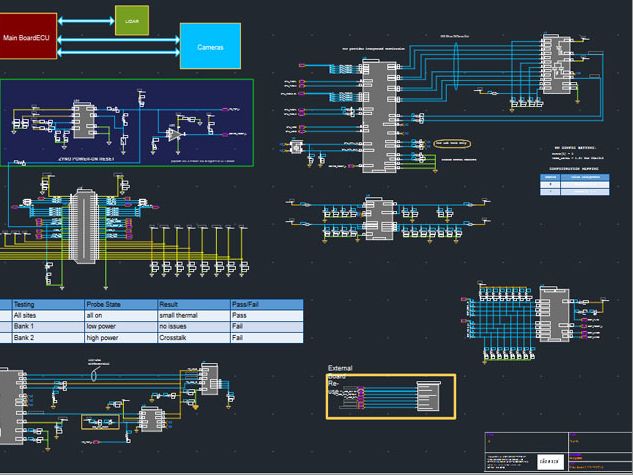

SoftBench Description

SoftBench is a desktop-grade test bench designed for body domain control systems such as ZCU, BDC, BCM, and VIU. It provides a complete environment for software development, hardware debugging, and system-level integration testing.

Capable of simulating over 400 I/O channels and equipped with configurable interface cards, SoftBench adapts easily to different ECU project requirements. It supports automated testing through CAN scripting, enabling fast, repeatable validation without manual intervention.

Built-in remote-control capability allows engineers to operate the test bench, monitor signals, and run automated sequences from anywhere—greatly enhancing distributed collaboration and cross-regional development. Additional functions such as sleep-current measurement, power-supply control, and robust I/O stimulation help replicate real vehicle conditions with high accuracy.

Compact, flexible, and powerful, SoftBench enables seamless collaboration, accelerates ECU development cycles, and improves overall testing efficiency.

Technical Parameters

| Part Number | Card | Function | IO/Card | Qty | Total IO |

|---|---|---|---|---|---|

| M00012-001 | Digital Board | Simulate high and low configurable digital input, and PWM input | 37 | 3 | 111 |

| M00013-001 | Resistor Board | Simulate analog input resistor range from 100 ohm to 91K ohm | 37 | 2 | 74 |

| M00014-001 | Analog Board | Simulate analog voltage (29 ch) and hall sensor signal (8 ch) | 37 | 2 | 74 |

| M00015-002 | Load Board | Simulate load for HSD/LSD/H bridge, and ADC feedback of output | 37 | 4 | 148 |

| M00011-001 | Power Board | Supply power and GND, measure sleep current | 37 | 1 | 37 |

| M00010-001 | Connect Board | Input of power and CAN, and RS232 for external control power supply | NA | 1 | NA |

| M00019-001 | Wireless Board | Wireless connection for remote control | NA | 1 | NA |

| M00020-001 | Break Board | Break connection between DUT and bench for debug | NA | 1 | NA |

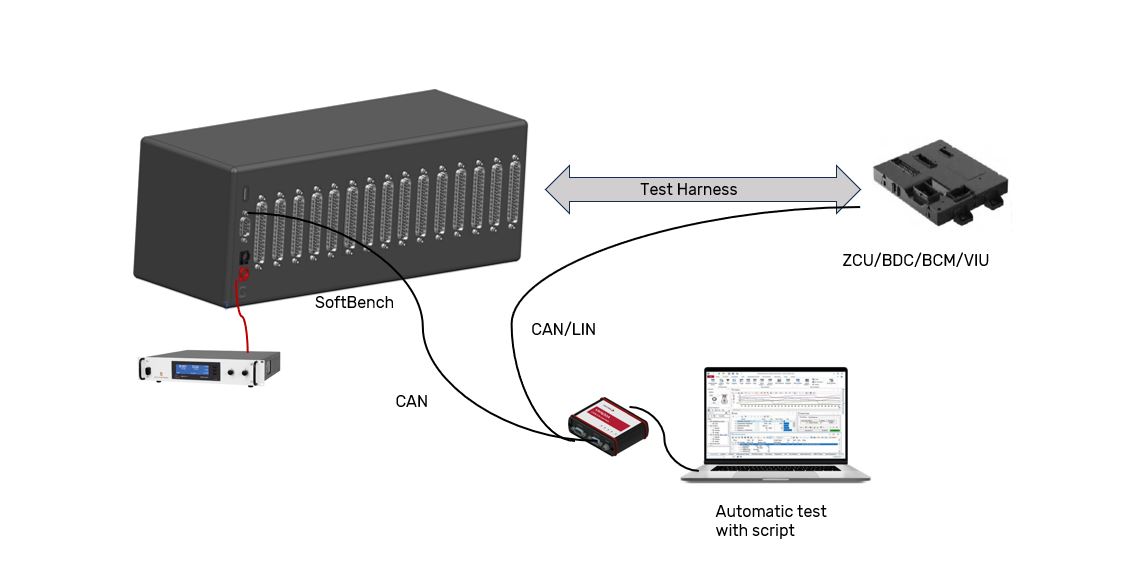

Application Scenario - CAN Script

Softbench can be integrated with CANcase to enable automated testing through CAN communication. By leveraging this connection, test sequences and device operations can be controlled directly from Softbench, allowing engineers to perform repeatable and precise testing of automotive or embedded systems without manual intervention. This setup is particularly useful for scenarios requiring high test efficiency, consistent signal generation, and automated data collection.

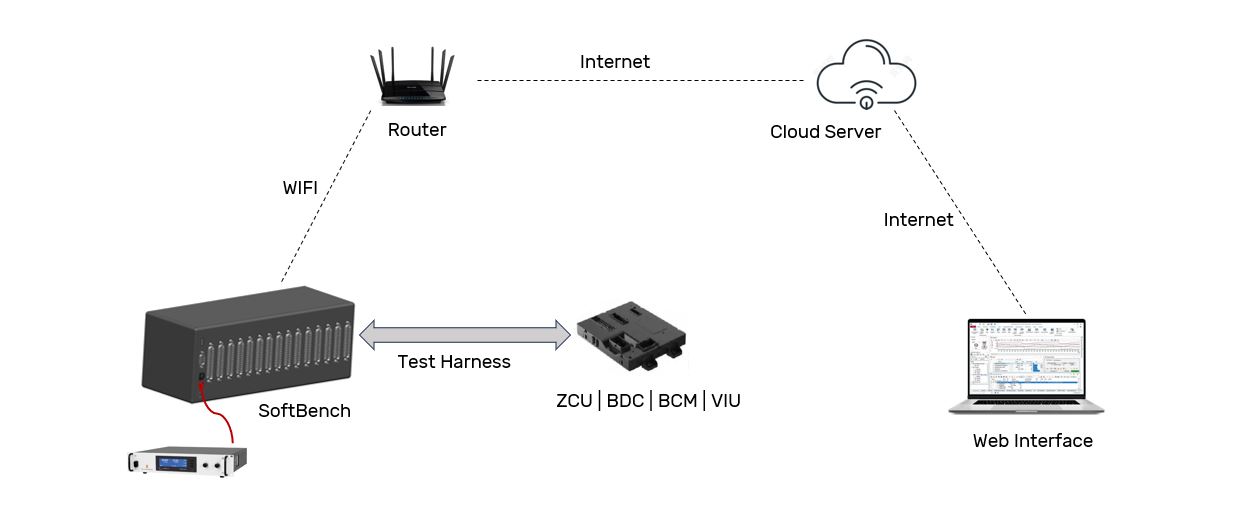

Application Scenario - Remote Control

Softbench also supports remote control testing via Wi-Fi. This capability allows engineers to operate tests and monitor devices from a distance, enabling flexible and efficient testing without being physically present in the lab. It is especially useful for long-duration tests, distributed testing setups, or situations where on-site access is limited, ensuring both convenience and reliable data acquisition.

Test System Customization

We can also provide customers with customized testing system solutions, tailored to meet their specific requirements. This service allows clients to have test setups that perfectly match their workflow, device types, and testing conditions, ensuring higher efficiency, accuracy, and flexibility in their testing processes.