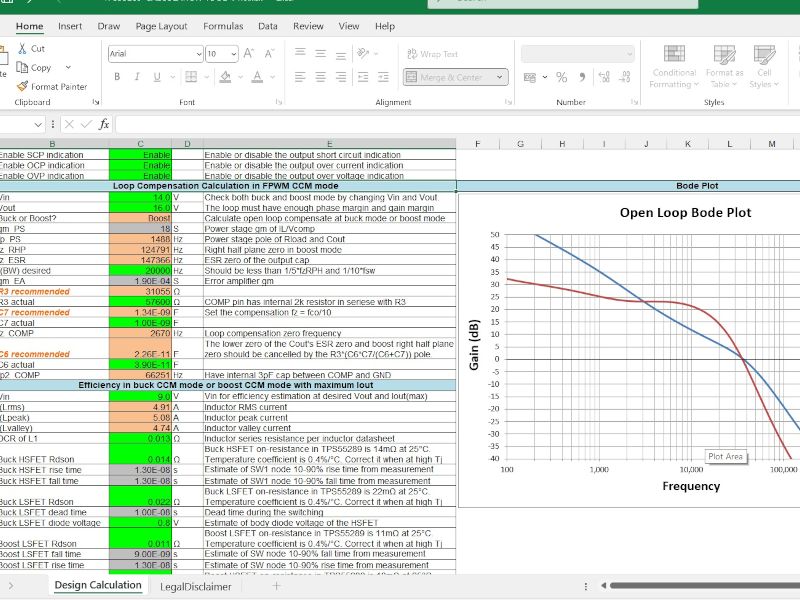

Worst-Case Circuit Analysis (WCCA)

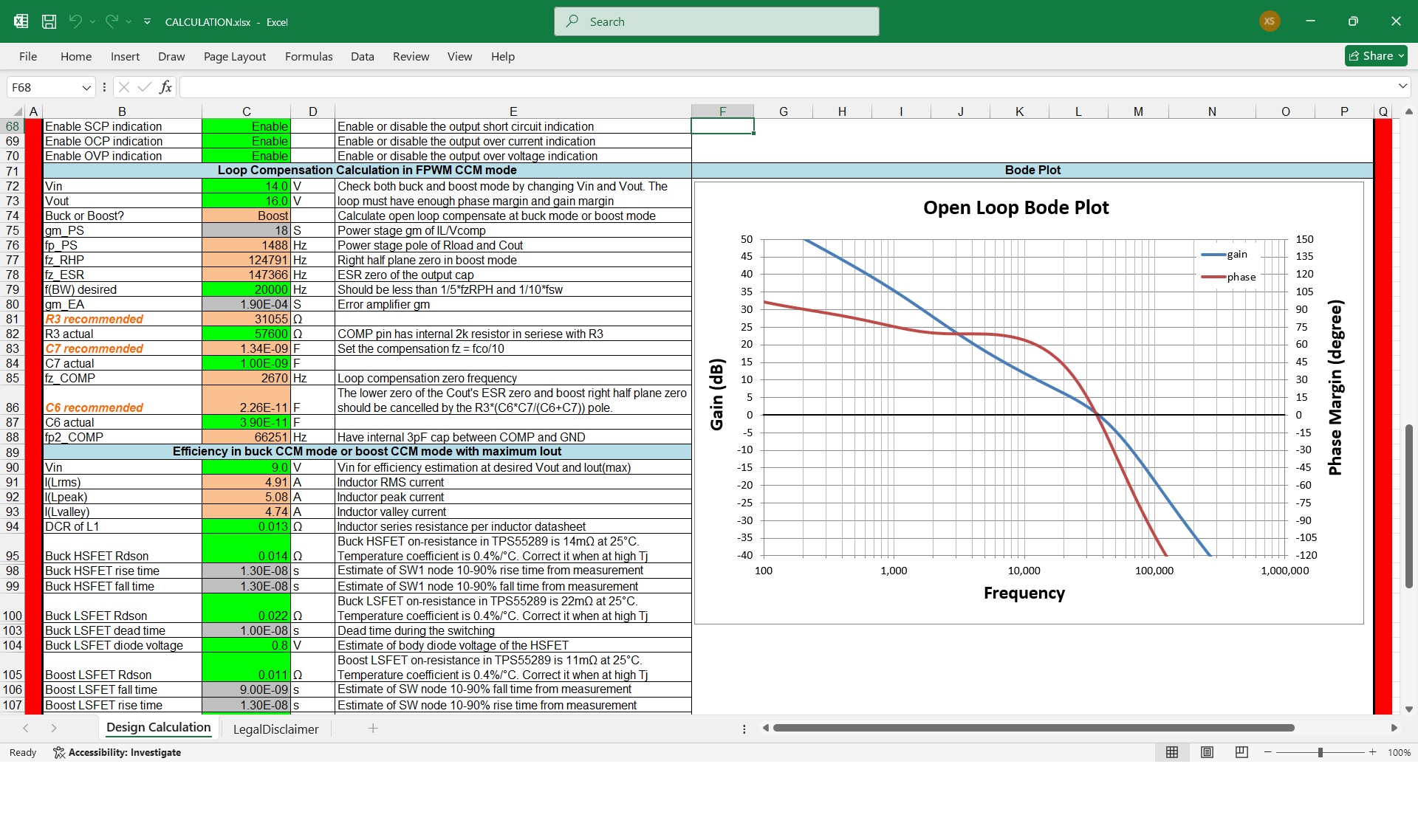

We provide comprehensive Worst-Case Circuit Analysis (WCCA) services to ensure the reliability, robustness, and compliance of automotive electronic designs under all operating extremes. Our workflow uses structured, Excel-based parametric modeling to evaluate component tolerances, temperature variations, aging effects, supply fluctuations, and worst-case functional limits. Each circuit block—power stages, protection networks, sensing interfaces, high-speed links, and safety-critical paths—is analyzed across its maximum and minimum boundary conditions to predict performance margins and identify potential design vulnerabilities.

Our WCCA process includes tolerance accumulation, Monte-Carlo-style evaluation, sensitivity analysis, stress assessment, and safety-related failure boundary modeling aligned with OEM and automotive standards. We generate clear, traceable Excel documents containing formulas, input parameters, limit checks, and automatic pass/fail indicators, enabling seamless design review and qualification documentation.

By combining analytical rigor with practical engineering insight, we help customers validate their circuits early, reduce design risk, prevent costly field issues, and meet stringent requirements for ASIL-level safety, long-term reliability, and production robustness.

Mathcad Engineering Calculation and Documentation Services

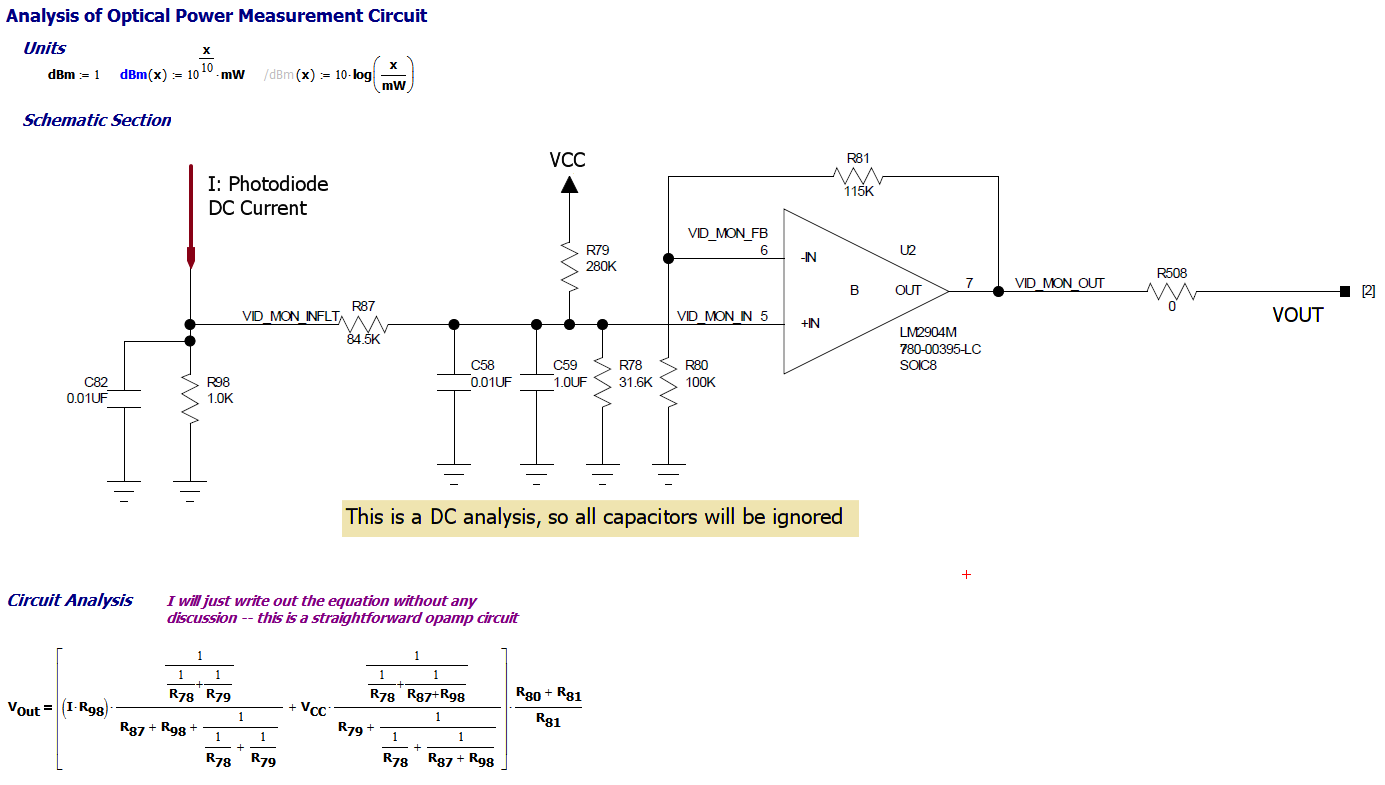

We offer specialized Mathcad-based engineering calculation services to support the design, analysis, and verification of automotive electronic systems. Using Mathcad’s symbolic and numeric computation capabilities, we develop structured, traceable engineering worksheets for power electronics, signal integrity, thermal analysis, sensor interfaces, protection circuits, reliability evaluation, and safety-critical calculations.

Our Mathcad models include parameterized formulas, tolerance analysis, automated limit checks, unit-consistent expressions, and visually organized engineering documentation that aligns with OEM and Tier-1 development standards. These worksheets help engineers validate design intent, evaluate design alternatives, and maintain a consistent calculation baseline throughout the project lifecycle.

With Mathcad, we deliver professional, review-ready calculation packages that enhance accuracy, reduce human error, and support compliance with industry requirements such as ASIL functional safety, DVP/validation planning, and design sign-off processes. By integrating Mathcad into the development workflow, we help customers accelerate design decisions, improve transparency, and ensure engineering rigor across complex automotive electronic designs.

PSPICE Circuit Simulation Services

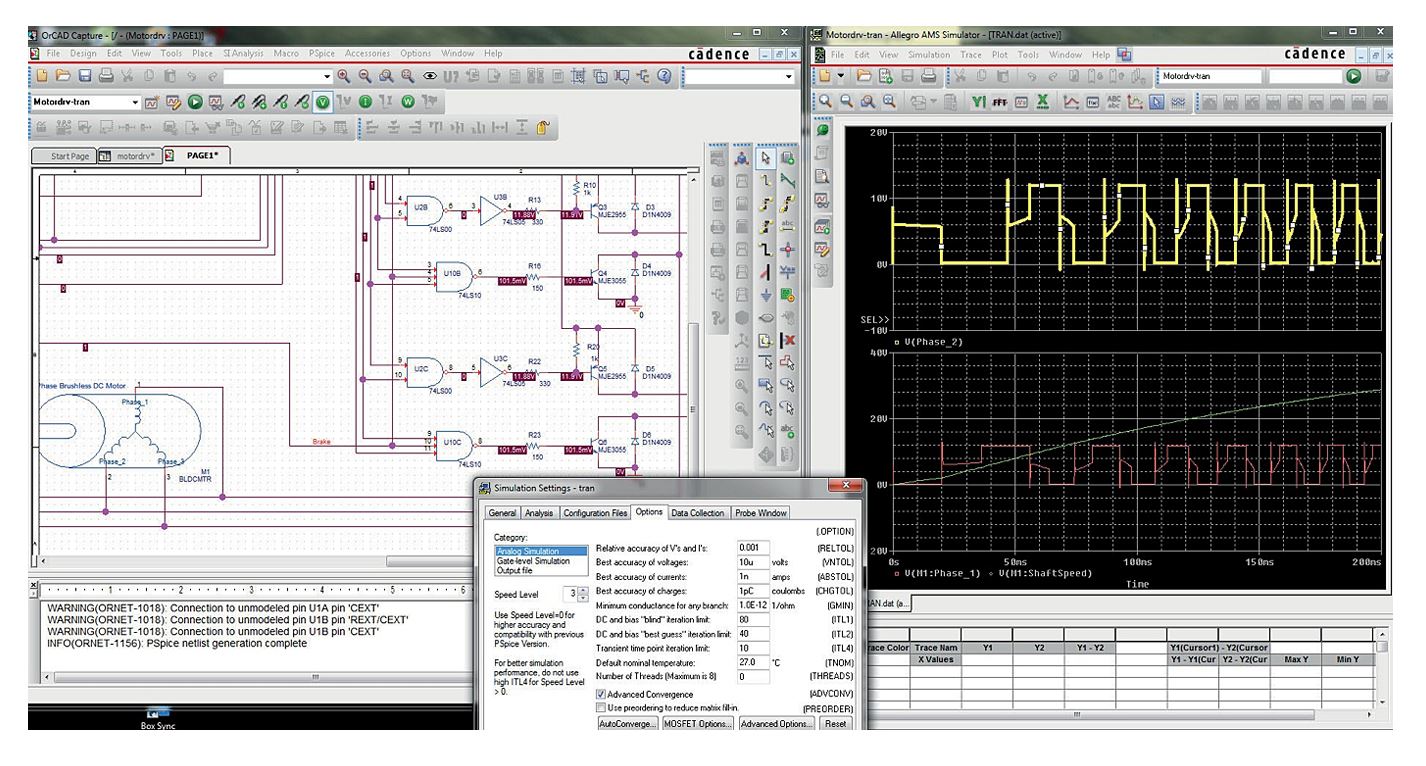

We provide comprehensive PSPICE simulation services to support accurate circuit validation, optimization, and design robustness assessment. Our team performs detailed behavioral, analog, mixed-signal, and power-stage simulations to verify circuit performance before hardware builds, helping customers reduce development risks and shorten design cycles.

Our capabilities include DC, AC, transient, Monte Carlo, worst-case, temperature-sweep, and parametric analyses. We model real-world component behavior using vendor-specific SPICE libraries, ensuring high-fidelity results that reflect actual production performance. Typical applications include power supply design validation, analog front-end tuning, signal conditioning evaluation, filter optimization, and protection-circuit behavior analysis.

By identifying potential issues early—such as instability, excessive ripple, startup anomalies, thermal stress, or component tolerance sensitivities—we help ensure your circuits meet functional, reliability, and performance targets before entering the prototyping stage.

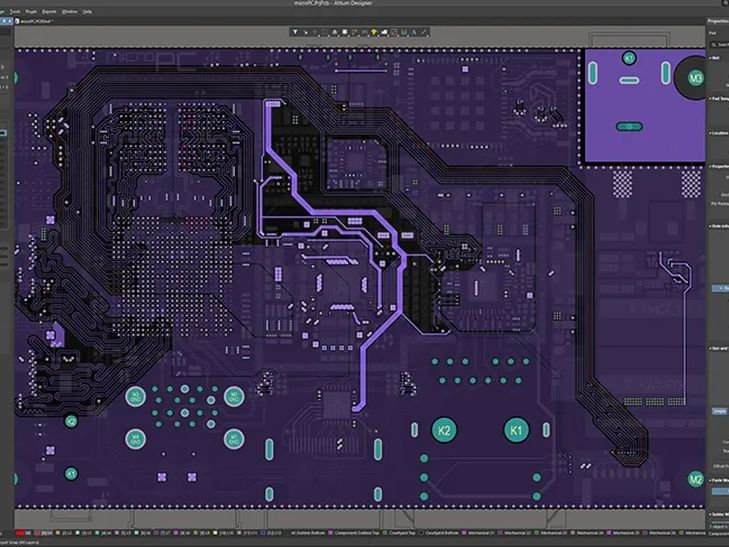

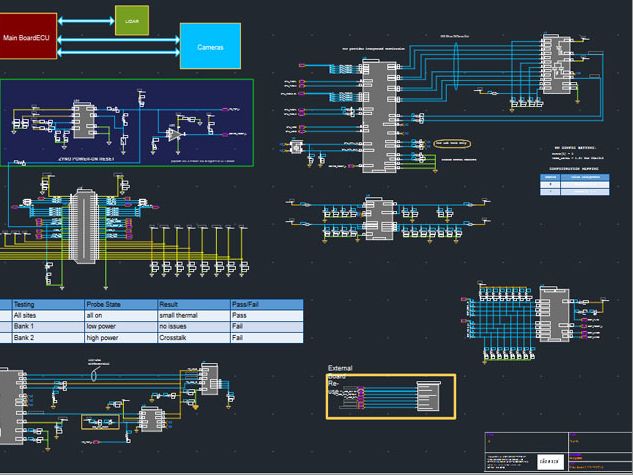

High-Speed Signal Integrity (SI) Simulation Services

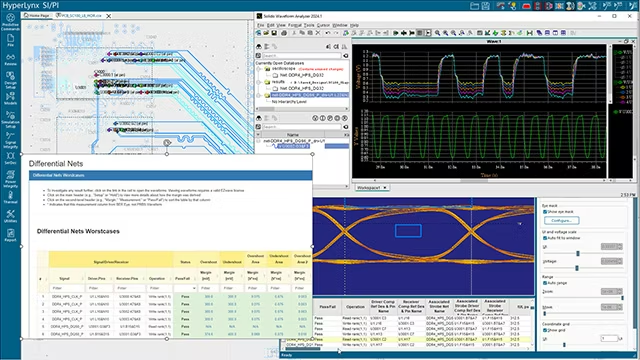

We provide advanced Signal Integrity (SI) simulation services to ensure robust performance of high-speed automotive electronic designs. Using industry-leading tools and methodology, we analyze the behavior of critical interfaces such as DDR/LPDDR memory, high-speed SerDes, automotive Ethernet (100/1000BASE-T1), PCIe, USB, and other multi-gigabit links.

Our SI workflow includes transmission-line modeling, impedance tuning, eye-diagram evaluation, jitter and skew analysis, crosstalk prediction, return-path verification, and topology optimization for both single-ended and differential signaling. We create accurate simulation models—including IBIS/IBIS-AMI, SPICE, and S-parameter data—to evaluate performance across voltage, temperature, stack-up variations, and manufacturing tolerances.

Through pre-layout and post-layout SI simulations, we help customers identify signal-integrity risks early, optimize routing strategies, validate stack-ups, and ensure compliance with OEM and interface-standard requirements.

By combining simulation expertise with deep automotive design experience, we deliver SI-validated, production-ready designs that reduce EMI risks, improve timing margins, and ensure reliable operation across all worst-case conditions.

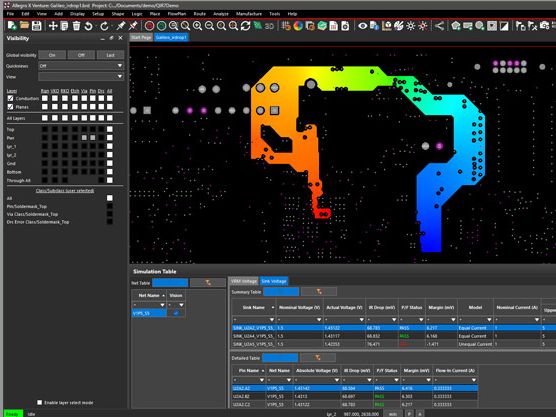

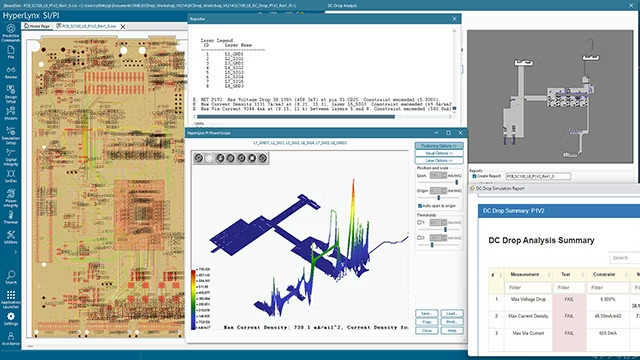

Power Integrity (PI) Simulation Services

We offer comprehensive Power Integrity (PI) simulation services to ensure stable, low-noise power delivery for high-speed automotive electronic systems. Our analysis covers complete PDN (Power Delivery Network) behavior—including DC, AC, and transient performance—to guarantee that processors, memory, SerDes, and mixed-signal components receive clean and reliable power under all operating conditions.

Our PI capabilities include DC IR-drop simulation, current-density analysis, AC impedance modeling, decoupling-network optimization, loop-stability evaluation, and transient load-step response verification. We develop optimized decoupling strategies, select appropriate capacitors, and tune stack-ups to achieve target impedance across frequency ranges defined by OEM or interface-standard requirements.

We assess resonances, plane noise, via effects, and switching-current impacts, enabling early detection of PI risks that can degrade SI performance, EMI behavior, or system stability. Both pre-layout and post-layout simulations are supported, allowing us to guide design architecture and validate the final PCB implementation.

Through data-driven PI analysis and deep automotive design expertise, we deliver robust power-delivery solutions that enhance system reliability, reduce noise, and accelerate customer time-to-market.

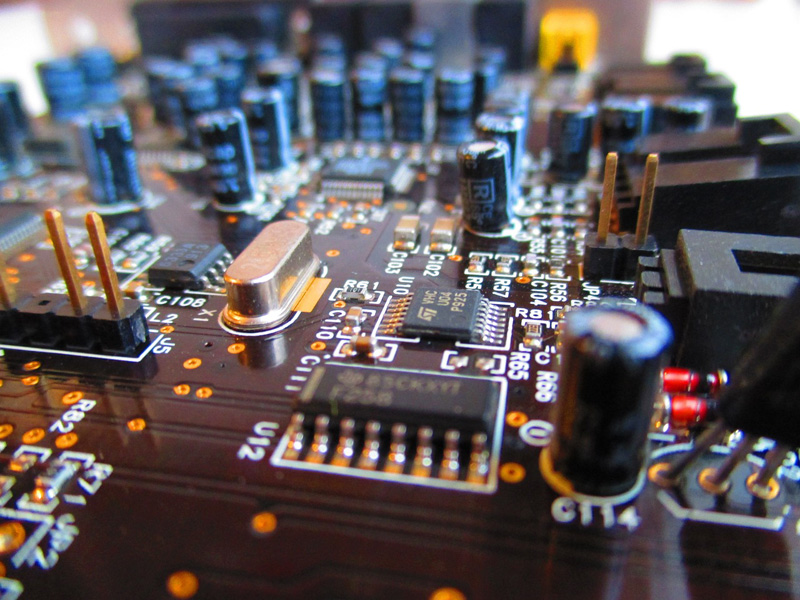

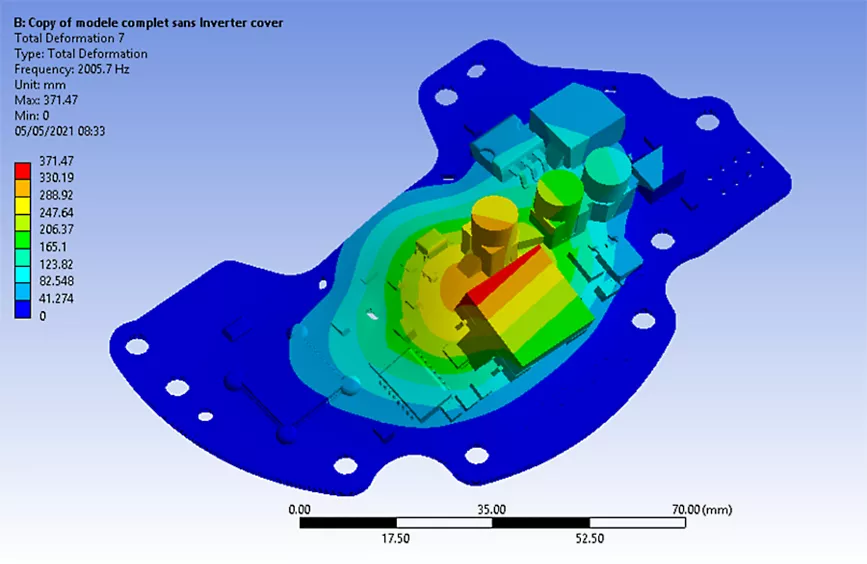

Reliability and GMW3172 Compliance Simulation Services

We provide advanced electronics reliability simulation services, leveraging Sherlock and other industry-standard tools to ensure automotive electronic designs meet stringent GMW3172 requirements. Our capabilities include physics-of-failure (PoF) based analysis of PCBs, ICs, and solder joints, assessing reliability under thermal cycling, mechanical vibration, shock, drop, and power-induced stresses.

Using Sherlock, we perform detailed fatigue life prediction, solder joint and component-level stress analysis, and material behavior modeling, enabling early identification of potential failure modes and risk mitigation. Combined with finite-element analysis (FEA) when necessary, we can evaluate complex board-level mechanical and thermal interactions, ensuring robust design for harsh automotive environments.

Our simulation workflow aligns with GMW3172 guidelines, covering vibration, shock, thermal cycling, and mechanical reliability verification for electronics assemblies. Deliverables include structured simulation reports, life prediction data, and actionable design recommendations, supporting OEM qualification, design reviews, and production readiness.

By integrating PoF-driven reliability analysis with GMW3172 compliance, we help customers reduce field failures, improve product robustness, and accelerate time-to-market for automotive electronic systems.

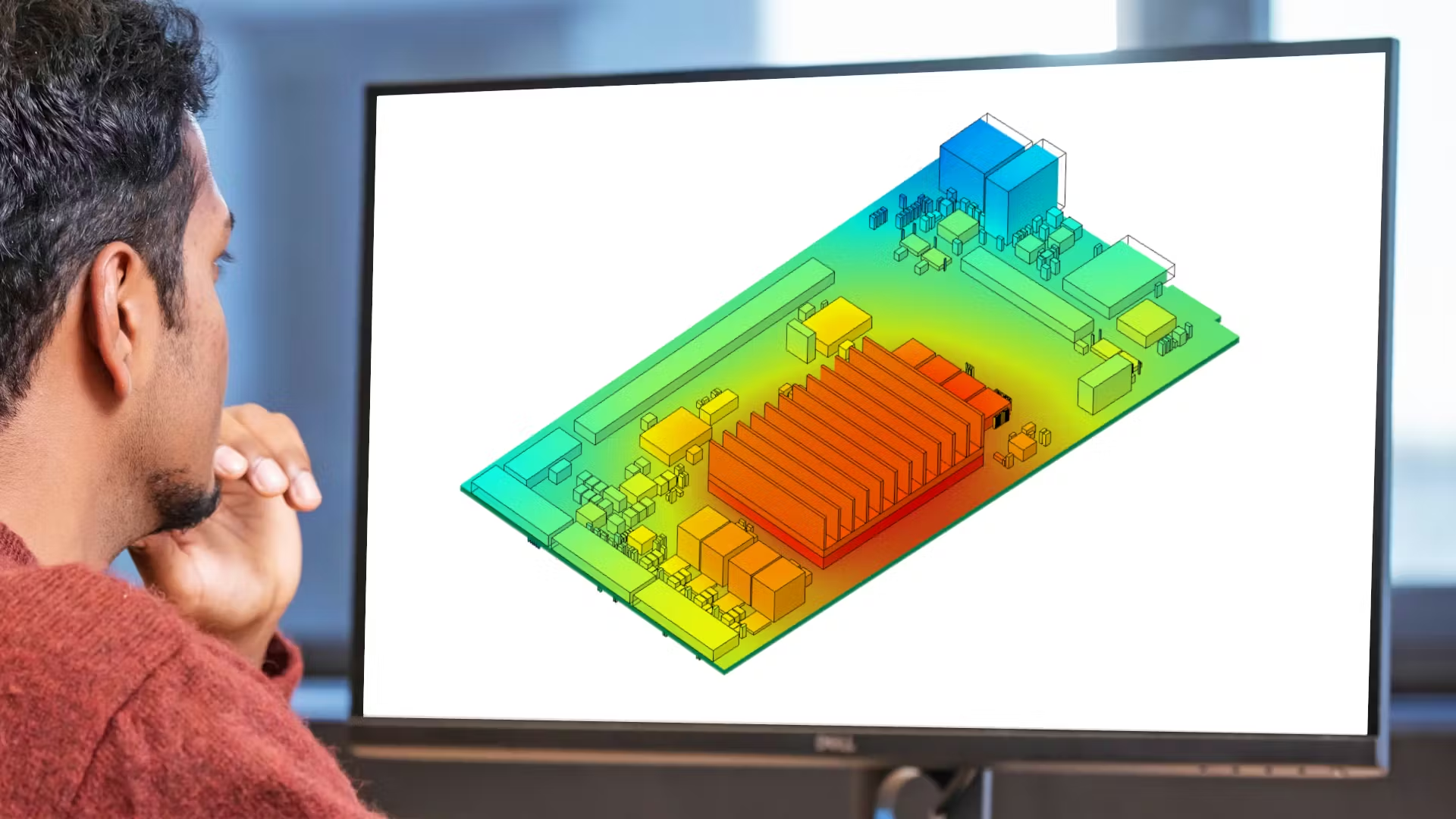

Thermal Simulation Services for Automotive Electronics

We provide comprehensive thermal simulation services to ensure reliable operation of automotive electronic systems under all operating conditions. Using advanced computational tools, we model heat generation, dissipation, and temperature distribution across PCBs, ICs, power modules, and complete electronic assemblies.

Our workflow includes steady-state and transient thermal analysis, hot-spot identification, airflow and cooling optimization, thermal interface material evaluation, and component placement guidance. We evaluate thermal coupling effects, junction-to-ambient and junction-to-case temperatures, and ensure that power and signal integrity are maintained under high-temperature conditions.

Thermal simulations are integrated with electrical and mechanical considerations to optimize system-level design, prevent overheating, reduce thermal-induced stress, and extend component lifetime. By providing actionable insights and validated thermal models, we help customers design robust, production-ready electronics that meet automotive reliability and safety standards.